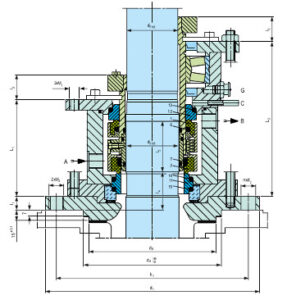

U164 Single & Dual Seals (Top-side Entry)

Product Description

- Single and Dual seal configuration

- Unbalanced design

- Independent of direction of rotation

- Cartridge construction

- Designed for top entry vessels

- Rotary unit with multiple springs

- Construction with Integrated bearing

also available - For glass-lined vessels, design

according to DIN 28138 T2 - U164 Single & Dual Seals (Top-side Entry)

| Details | |

|---|---|

| Item No. | Description |

| 1 | Seal face, atmosphere side |

| 2 | Seal face, product side |

| 6, 7, 13, 14, 15 | O-Ring |

| 11 | Seat, product side |

| 12 | Seat, atmosphere side |

- Available with or without floating bearing

- Double seals can be applied at higher pressure and rotating speed

- Suitable for standardizations

- Rugged design to ensure long term reliability and operating life

- Seals are assembled in cartridge construction for easy fitment

- Over all connecting dimensions are tailor made to customer's specifications

- The seal design is unique as it closes due to the hydraulic product pressure as well as overlaying barrier pressure

- Chemical industry

- Non-toxic media with single seal

- Pharmaceutical industry

- Toxic media with double seal

- Agitators

- Reactors

- FDA

DIN 28136 T3 (for glass-lined vessels)

DIN 28137 T2 (flange connection for glasslined vessels)

DIN 28159 (shaft end for glass-lined vessels)

- Options:

Cooling or heating flange Leakage drain, flush or heating flange

Leakage drain or flush

Polymerization barrier, leakage drain or flush

- According to application and customer's specifications

- Sizes: d3 = Upto 160 mm (Upto 6.500’’)

- Pressure: p1 = vacuum ... 16 bar (232 PSI), p3 = max. 18 bar (261 PSI)

- Temperature: t1 = -40 °C ... +200 (250) °C (-40 °F ...

+392 (482) °F)

Speed = 0 ... 5 m/s (0 ... 16 ft/s)